- Notwendige Cookies helfen dabei, eine Webseite nutzbar zu machen, indem sie Grundfunktionen wie Seitennavigation und Zugriff auf sichere Bereiche der Webseite ermöglichen. Die Webseite kann ohne diese Cookies nicht richtig funktionieren.

- th-deg.de4_pc_sesDer Session-Cookie (auch bekannt als transienter Cookie) ist für den Aufbau der Verbindung und die korrekte Auslieferung von Website-Inhalten zwischen Browser und dem Webserver bei PHP-Systemen notwendig. Dieser Cookie wird nach dem Websitezugriff wieder gelöscht. Die Session Cookies dienen nur der korrekten Funktionsweise unseres Systems und werden keiner anderen Verwendung zugeführt.PHPSESSIDBehält die Zustände des Benutzers bei allen Seitenanfragen bei.searchstateSpeichert die Zustimmung/Ablehnung des Benutzers zur Benutzung der Google SuchmaschinevorlesungenviewDieser wird nur im my.th-deg.de View "Stundenplan" gesetzt und speichert den Wert der ausgewählten Ansicht (Listenansicht/Tages-Wockenansicht)

- th-deg.de

- Präferenz-Cookies ermöglichen einer Webseite sich an Informationen zu erinnern, die die Art beeinflussen, wie sich eine Webseite verhält oder aussieht, wie z. B. Ihre bevorzugte Sprache oder die Region in der Sie sich befinden.

- Matterport1Erfahren Sie mehr über diesen Anbietersc_anonymous_idWird im Zusammenhang mit der 3D-Ansichtsfunktion auf der Website verwendet.

- YouTube1Erfahren Sie mehr über diesen AnbieterVISITOR_INFO1_LIVEYoutube-Cookie. Versucht, die Benutzerbandbreite auf Seiten mit integrierten YouTube-Videos zu schätzen.

- cdn-2.matterport.com

vimeo.com3_cfuvid [x3]Dieses Cookie ist ein Teil der Dienste von Cloudflare - einschließlich Lastverteilung, Bereitstellung von Website-Inhalten und Bereitstellung einer DNS-Verbindung für Website-Betreiber. - consent.cookiebot.eu

zaf.th-deg.de2CookieConsent [x2]Speichert den Zustimmungsstatus des Benutzers für Cookies auf der aktuellen Domäne. - letscast.fm1_lets_cast_sessionAnstehend

- nextcloud.th-deg.de4__Host-nc_sameSiteCookielaxAnstehend__Host-nc_sameSiteCookiestrictAnstehendoc_sessionPassphraseBehält die Zustände des Nutzers bei allen Seitenanfragen bei.ocl3ir5nxzaeAnstehend

- th-deg.de1headerstateSpeichert die Auswahl von Header maximieren oder minimieren

- widget.sndcdn.com1sc_anonymous_idWird im Zusammenhang mit der 3D-Ansichtsfunktion auf der Website verwendet.

- Matterport

- Statistik-Cookies helfen Webseiten-Besitzern zu verstehen, wie Besucher mit Webseiten interagieren, indem Informationen anonym gesammelt und gemeldet werden.

- Google6Erfahren Sie mehr über diesen Anbieter

Ein Teil der Daten, die dieser Anbieter gesammelt hat, dient der Personalisierung und der Messung der Werbewirksamkeit.

test_cookieVerwendet, um zu überprüfen, ob der Browser des Benutzers Cookies unterstützt.collectWird verwendet, um Daten zu Google Analytics über das Gerät und das Verhalten des Besuchers zu senden. Erfasst den Besucher über Geräte und Marketingkanäle hinweg._gaRegistriert eine eindeutige ID, die verwendet wird, um statistische Daten dazu, wie der Besucher die Website nutzt, zu generieren._ga_#Sammelt Daten dazu, wie oft ein Benutzer eine Website besucht hat, sowie Daten für den ersten und letzten Besuch. Von Google Analytics verwendet._gatWird von Google Analytics verwendet, um die Anforderungsrate einzuschränken_gidRegistriert eine eindeutige ID, die verwendet wird, um statistische Daten dazu, wie der Besucher die Website nutzt, zu generieren. - Soundcloud1Erfahren Sie mehr über diesen Anbieternumber(#)Wird verwendet, um die Interaktion der Nutzer mit eingebetteten Inhalten zu verfolgen.

- Vimeo2Erfahren Sie mehr über diesen Anbieter__cf_bmDieser Cookie wird verwendet, um zwischen Menschen und Bots zu unterscheiden. Dies ist vorteilhaft für die webseite, um gültige Berichte über die Nutzung ihrer webseite zu erstellen.vuidSammelt Daten über Besuche des Benutzers auf der Website, wie zum Beispiel welche Seiten gelesen wurden.

- YouTube1Erfahren Sie mehr über diesen AnbieterYSCYoutube-Cookie. Registriert eine eindeutige ID, um Statistiken der Videos von YouTube, die der Benutzer gesehen hat, zu behalten.

- th-deg.de3_pc_tvsSpeichert einen eindeutigen Hashwert für das Pimcore interne Targeting-System für die Auswertung anonymer Nutzungsdaten_pc_visAnonymisierte "Besucher-ID" für das Pimcore interne Targeting-System für die Auswertung anonymer Nutzungsdaten_ptg.userSpeichert die Session, anonymisierte Besucher-ID und den Aktivitäts-Logstatus für das Pimcore interne Targeting-System für die Auswertung anonymer Nutzungsdaten

- Google

- Marketing-Cookies werden verwendet, um Besuchern auf Webseiten zu folgen. Die Absicht ist, Anzeigen zu zeigen, die relevant und ansprechend für den einzelnen Benutzer sind und daher wertvoller für Publisher und werbetreibende Drittparteien sind.

- Meta Platforms, Inc.4Erfahren Sie mehr über diesen AnbieterlastExternalReferrerErmittelt, wie der Nutzer die Website erreicht hat, indem seine letzte URL-Adresse registriert wird.lastExternalReferrerTimeErmittelt, wie der Nutzer die Website erreicht hat, indem seine letzte URL-Adresse registriert wird.topicsLastReferenceTimeSammelt websiteübergreifende Daten über den Besucher - Diese Daten werden verwendet, um die Relevanz der Werbung zu erhöhen._fbpWird von Facebook genutzt, um eine Reihe von Werbeprodukten anzuzeigen, zum Beispiel Echtzeitgebote dritter Werbetreibender.

- Google5Erfahren Sie mehr über diesen Anbieter

Ein Teil der Daten, die dieser Anbieter gesammelt hat, dient der Personalisierung und der Messung der Werbewirksamkeit.

IDEVerwendet von Google DoubleClick, um die Handlungen des Benutzers auf der Webseite nach der Anzeige oder dem Klicken auf eine der Anzeigen des Anbieters zu registrieren und zu melden, mit dem Zweck der Messung der Wirksamkeit einer Werbung und der Anzeige zielgerichteter Werbung für den Benutzer.NIDRegistriert eine eindeutige ID, die das Gerät eines wiederkehrenden Benutzers identifiziert. Die ID wird für gezielte Werbung genutzt.pagead/1p-user-list/#Wird verwendet, um zu tracken, ob der Besucher Interesse an bestimmten Produkten oder Ereignissen auf mehreren Websites gezeigt hat und wie der Besucher zwischen den Websites navigiert - Dies wird zur Messung des Werbeaufwands verwendet und erleichtert die Zahlung von Empfehlungsgebühren zwischen Websites._gcl_auWird von Google AdSense zum Experimentieren mit Werbungseffizienz auf Webseiten verwendet, die ihre Dienste nutzen._gcl_lsVerfolgt die Konversionsrate zwischen dem Nutzer und den Werbebannern auf der Website - Dies dient der Optimierung der Relevanz der Werbung auf der Website. - YouTube34Erfahren Sie mehr über diesen Anbieter#-# [x2]Wird verwendet, um die Interaktion der Nutzer mit eingebetteten Inhalten zu verfolgen.iU5q-!O9@[#COOKIETABLE_ADVERTISING#]nbsp;[x2]Registriert eine eindeutige ID, um Statistiken der Videos von YouTube, die der Benutzer gesehen hat, zu behalten.LAST_RESULT_ENTRY_KEY [x2]Wird verwendet, um die Interaktion der Nutzer mit eingebetteten Inhalten zu verfolgen.nextId [x2]Wird verwendet, um die Interaktion der Nutzer mit eingebetteten Inhalten zu verfolgen.requests [x2]Wird verwendet, um die Interaktion der Nutzer mit eingebetteten Inhalten zu verfolgen.yt.innertube::nextIdRegistriert eine eindeutige ID, um Statistiken der Videos von YouTube, die der Benutzer gesehen hat, zu behalten.ytidb::LAST_RESULT_ENTRY_KEY [x2]Wird verwendet, um die Interaktion der Nutzer mit eingebetteten Inhalten zu verfolgen.YtIdbMeta#databases [x2]Wird verwendet, um die Interaktion der Nutzer mit eingebetteten Inhalten zu verfolgen.yt-remote-cast-available [x2]Speichert die Benutzereinstellungen beim Abruf eines auf anderen Webseiten integrierten Youtube-Videosyt-remote-cast-installed [x2]Speichert die Benutzereinstellungen beim Abruf eines auf anderen Webseiten integrierten Youtube-Videosyt-remote-connected-devices [x2]Speichert die Benutzereinstellungen beim Abruf eines auf anderen Webseiten integrierten Youtube-Videosyt-remote-device-id [x2]Speichert die Benutzereinstellungen beim Abruf eines auf anderen Webseiten integrierten Youtube-Videosyt-remote-fast-check-period [x2]Speichert die Benutzereinstellungen beim Abruf eines auf anderen Webseiten integrierten Youtube-Videosyt-remote-session-app [x2]Speichert die Benutzereinstellungen beim Abruf eines auf anderen Webseiten integrierten Youtube-Videosyt-remote-session-name [x2]Speichert die Benutzereinstellungen beim Abruf eines auf anderen Webseiten integrierten Youtube-Videos__Secure-ROLLOUT_TOKENAnstehendLogsDatabaseV2:V#||LogsRequestsStoreWird verwendet, um die Interaktion der Nutzer mit eingebetteten Inhalten zu verfolgen.remote_sidNotwendig für die Implementierung und Funktionalität von YouTube-Videoinhalten auf der Website.ServiceWorkerLogsDatabase#SWHealthLogNotwendig für die Implementierung und Funktionalität von YouTube-Videoinhalten auf der Website.TESTCOOKIESENABLEDWird verwendet, um die Interaktion der Nutzer mit eingebetteten Inhalten zu verfolgen.

- Meta Platforms, Inc.

- Nicht klassifizierte Cookies sind Cookies, die wir gerade versuchen zu klassifizieren, zusammen mit Anbietern von individuellen Cookies.

- Cloudflare1Erfahren Sie mehr über diesen Anbietercf.turnstile.uAnstehend

- th-deg.de2_pc_tssAnstehendsymfony/profiler/toolbar/displayStateAnstehend

- Cloudflare

Laut Gesetz können wir Cookies auf Ihrem Gerät speichern, wenn diese für den Betrieb dieser Seite unbedingt notwendig sind. Für alle anderen Cookie-Typen benötigen wir Ihre Erlaubnis.

Diese Seite verwendet unterschiedliche Cookie-Typen. Einige Cookies werden von Drittparteien platziert, die auf unseren Seiten erscheinen.

Sie können Ihre Einwilligung jederzeit von der Cookie-Erklärung auf unserer Website ändern oder widerrufen.

Erfahren Sie in unserer Datenschutzrichtlinie mehr darüber, wer wir sind, wie Sie uns kontaktieren können und wie wir personenbezogene Daten verarbeiten.

Bitte geben Sie Ihre Einwilligungs-ID und das Datum an, wenn Sie uns bezüglich Ihrer Einwilligung kontaktieren.

The focus is on the controlled condition monitoring of functionally integrated structural dynamic systems. Examples include the identification and simulation of the load spectrum of load-bearing systems such as frame and bearing structures, spring-damper systems, load-bearing structures, the vibration, stability and load redistribution control of such systems as well as the evaluation of reliability and data and model form uncertainty using numerical verification and experimental calibration and validation procedures based on Bayesian inference methods.

The focus is on the controlled condition monitoring of functionally integrated structural dynamic systems. Examples include the identification and simulation of the load spectrum of load-bearing systems such as frame and bearing structures, spring-damper systems, load-bearing structures, the vibration, stability and load redistribution control of such systems as well as the evaluation of reliability and data and model form uncertainty using numerical verification and experimental calibration and validation procedures based on Bayesian inference methods. Electrical movement platform on eight legs (octopods)

Electrical movement platform on eight legs (octopods) Temperature range: -40 °C to +70 °C

Temperature range: -40 °C to +70 °C The aim of the investigations is to identify and evaluate the uncertainty in various mathematical models for predicting passive and active vibration isolation. In this context, active vibration isolation means that an additional force controlled by velocity-proportional feedback (amplification factor g) significantly increases the vibration isolation effect compared to passive vibration isolation without the additional force. As seen in the conceptual design, a two leaf springs (bending stiffness YI and stiffness coefficient k) with adjustable lengths l and a voice coil actuator (damping coefficient b, amplification factor g). The frame is also mounted to vibrate via elastic bands (damping coefficient b_f≪b and stiffness coefficient k_f≪k). A modelling hammer generates an impulse on the frame, which is passed on to the vibrating mass m as a displacement excitation and causes it to vibrate.

The aim of the investigations is to identify and evaluate the uncertainty in various mathematical models for predicting passive and active vibration isolation. In this context, active vibration isolation means that an additional force controlled by velocity-proportional feedback (amplification factor g) significantly increases the vibration isolation effect compared to passive vibration isolation without the additional force. As seen in the conceptual design, a two leaf springs (bending stiffness YI and stiffness coefficient k) with adjustable lengths l and a voice coil actuator (damping coefficient b, amplification factor g). The frame is also mounted to vibrate via elastic bands (damping coefficient b_f≪b and stiffness coefficient k_f≪k). A modelling hammer generates an impulse on the frame, which is passed on to the vibrating mass m as a displacement excitation and causes it to vibrate.

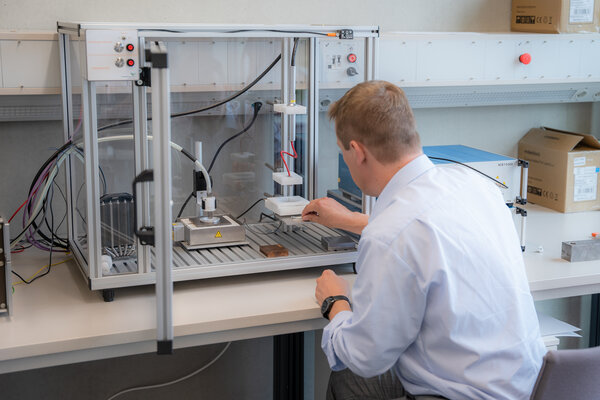

The setup is used for controlled charging and discharging of polymer samples. Charging takes place via corona discharge by depositing negative or positive charges on the sample surface. The charge density or surface potential is very precisely pre-set and controlled. The samples are then discharged isothermally or thermally stimulated and the decay of the surface potential is recorded and stored on the computer as a discharge curve. The discharge curves provide important information about the processes of charge storage and charge transport in dielectrics. These findings are then used in the development of new types of actuators and sensors as well as high-voltage insulation.

The setup is used for controlled charging and discharging of polymer samples. Charging takes place via corona discharge by depositing negative or positive charges on the sample surface. The charge density or surface potential is very precisely pre-set and controlled. The samples are then discharged isothermally or thermally stimulated and the decay of the surface potential is recorded and stored on the computer as a discharge curve. The discharge curves provide important information about the processes of charge storage and charge transport in dielectrics. These findings are then used in the development of new types of actuators and sensors as well as high-voltage insulation.

Piezoelectricity is the occurrence of an electrical voltage on solids when they are elastically deformed. Various modern actuators and sensors are constructed on the basis of piezoelectric materials. Some polymer materials have piezoelectric properties, making them so-called smart materials. The experimental setup is used to measure their piezoelectric coefficients. The samples are excited using a sinusoidal force and the resulting voltage signals are recorded with the measuring amplifier.

Piezoelectricity is the occurrence of an electrical voltage on solids when they are elastically deformed. Various modern actuators and sensors are constructed on the basis of piezoelectric materials. Some polymer materials have piezoelectric properties, making them so-called smart materials. The experimental setup is used to measure their piezoelectric coefficients. The samples are excited using a sinusoidal force and the resulting voltage signals are recorded with the measuring amplifier.

This project is funded by the European Social Fund.

This project is funded by the European Social Fund.